In utility-scale solar and energy storage projects, Balance of System (BOS) costs often represent a substantial portion of the total Capital Expenditure (CAPEX). While modules and inverters get much of the attention, the expenses associated with wiring, mounting, switchgear, and labor can make or break a project's financial viability. This case study examines how a 1 MW photovoltaic and energy storage system (PV-ESS) achieved significant BOS CAPEX reduction through the strategic implementation of Rapid Shutdown (RSD) technology.

The Challenge: Unpacking BOS Costs in Megawatt-Scale Systems

Deploying a 1 MW PV-ESS involves more than just panels and batteries. The infrastructure that connects and controls these components is complex and costly. Understanding these costs is the first step toward optimization.

Identifying Major CAPEX Contributors

For large commercial or utility projects, BOS costs are a critical financial component. The primary drivers include DC and AC cabling, combiners, switchgear, transformers, and the labor required for installation. According to research on electricity storage valuation, the annualized investment costs are a main CAPEX component. As highlighted in reports like the Electricity Storage Valuation Framework, managing these upfront expenditures is crucial for project success. In a 1 MW system, the sheer volume of copper wiring and the complexity of high-voltage DC circuits contribute heavily to the final bill.

The Safety Imperative and Its Cost Implications

Modern electrical codes, such as the NEC in the United States, mandate stringent safety measures for PV systems. Rapid Shutdown functionality, which de-energizes conductors outside the array boundary, is a key requirement. Traditionally, meeting these codes involved additional, often expensive, equipment that could inflate the BOS budget. The challenge was to meet these non-negotiable safety standards without escalating costs.

Project Overview: A 1 MW PV-ESS Installation

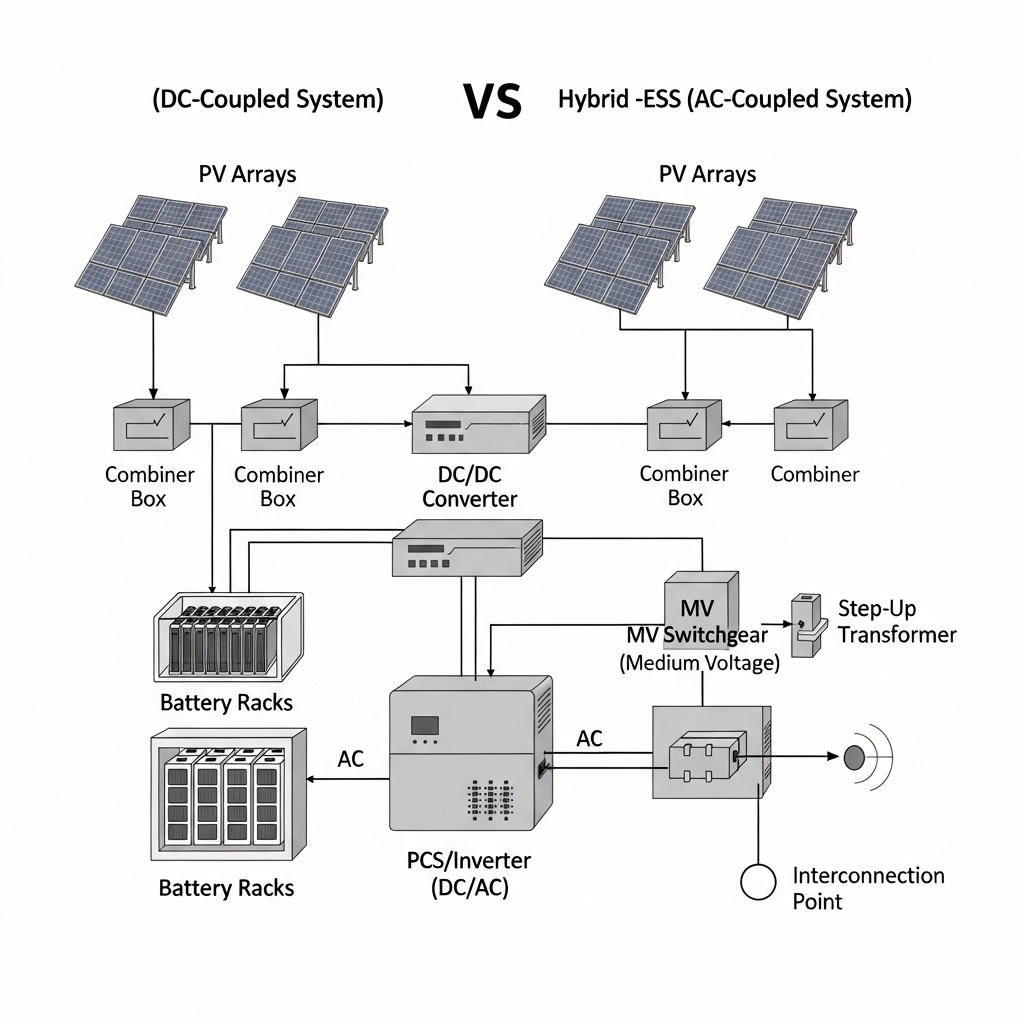

This case study focuses on a commercial-scale project featuring a 1-megawatt solar array paired with a 2-megawatt-hour battery energy storage system (BESS). The goal was to power a large industrial facility, reduce peak demand charges, and ensure energy resilience.

System Specifications

The project utilized high-efficiency monocrystalline solar panels and a LiFePO4 (Lithium Iron Phosphate) battery bank. The initial design followed a conventional approach with string inverters and DC combiners, projecting a standard BOS cost structure.

The Initial Cost Projection

The preliminary budget allocated a significant percentage of the total CAPEX to BOS components. The table below illustrates the estimated costs for key electrical BOS elements in a traditional design without integrated RSD at the module level.

| BOS Component | Estimated Cost (USD) | Percentage of Electrical BOS |

|---|---|---|

| DC Cabling & Conduit | $95,000 | 35% |

| DC Combiners & Disconnects | $55,000 | 20% |

| Switchgear & Protection | $40,000 | 15% |

| Installation Labor (Electrical) | $82,000 | 30% |

| Total Estimated Cost | $272,000 | 100% |

Disclaimer: These figures are illustrative for this case study and do not constitute a formal quote or financial advice. Actual project costs can vary based on location, equipment selection, and labor rates.

The Solution: Strategic Integration of Module-Level RSD

Instead of viewing RSD as simply another required component, the project team approached it as a tool for system-wide cost optimization. By selecting a system with RSD functionality integrated at the module level, they fundamentally altered the system's electrical architecture.

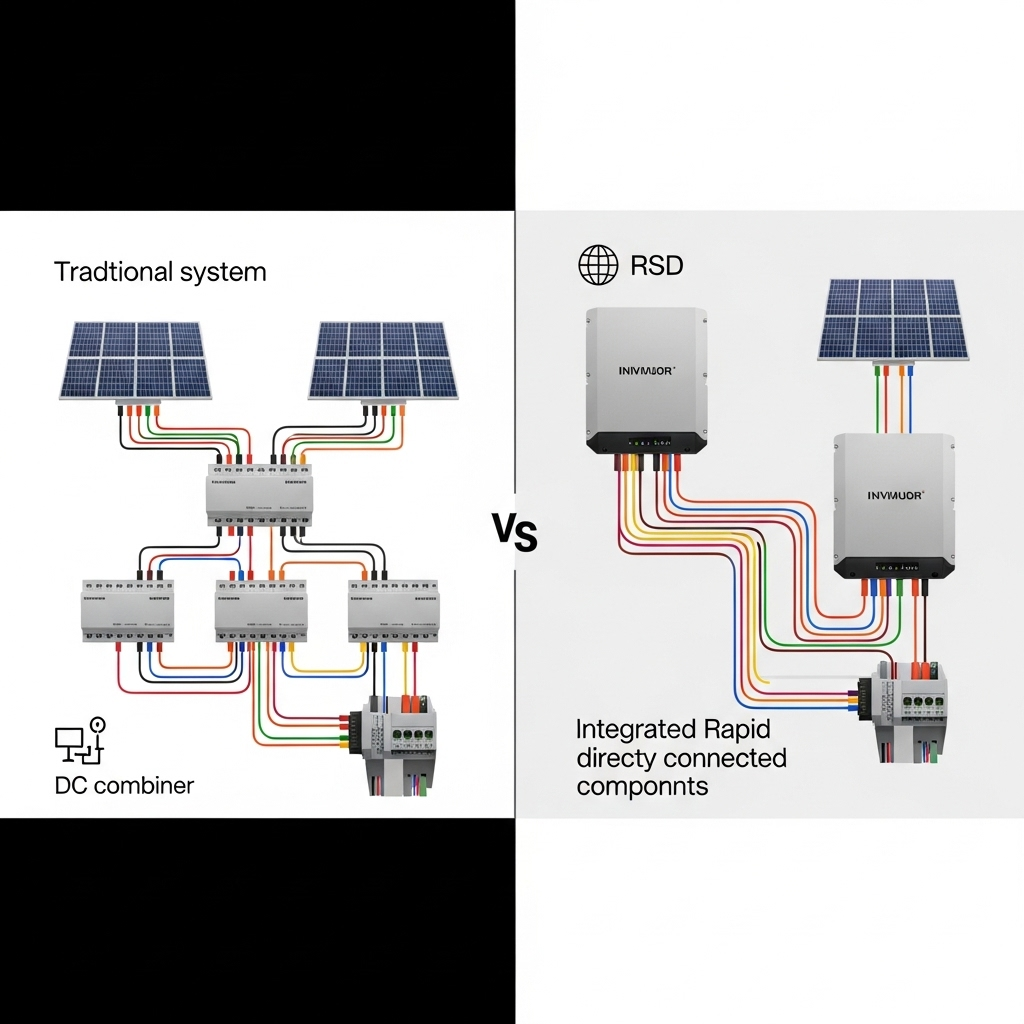

How RSD Simplifies System Architecture

Module-Level Power Electronics (MLPE) with integrated RSD eliminate the need for traditional DC combiners and reduce the complexity of DC wiring. Since each module can be rapidly and individually shut down at the source, the high-voltage DC runs through the conduit are controlled. This allows for more flexible system design, often reducing the length and gauge of the required copper wiring. The IEA's technology roadmap for solar has long pointed towards technological improvements that drive down costs, and this architectural simplification is a prime example of that trend in action.

Quantifying the CAPEX Reduction

The revised design led to direct and quantifiable savings. The simplified wiring and elimination of components resulted in a significant reduction in material costs and the labor needed to install them. The following table compares the initial projection with the final costs after implementing the RSD-based strategy.

| BOS Component | Initial Estimated Cost | Final Cost with Integrated RSD | Savings |

|---|---|---|---|

| DC Cabling & Conduit | $95,000 | $70,000 | $25,000 |

| DC Combiners & Disconnects | $55,000 | $15,000 | $40,000 |

| Switchgear & Protection | $40,000 | $38,000 | $2,000 |

| Installation Labor (Electrical) | $82,000 | $60,000 | $22,000 |

| Total Cost | $272,000 | $183,000 | $89,000 (32.7% Reduction) |

Beyond Material Savings: Reduced Labor and Faster Commissioning

The 32.7% reduction in electrical BOS CAPEX is a compelling figure. A major contributor was the decrease in labor hours. With fewer components to mount and wire, the electrical team completed their work faster. This accelerated the overall project timeline, allowing for quicker commissioning and a faster path to generating returns on the investment.

Analyzing the Long-Term Value Proposition

The benefits of this approach extend beyond the initial capital savings. A well-designed system offers value throughout its operational life.

Enhanced Safety and O&M

The primary function of RSD is safety, providing a controlled, de-energized environment for maintenance personnel and first responders. Furthermore, the module-level data that often accompanies these systems provides unprecedented visibility into system performance. Technicians can pinpoint underperforming or faulty modules remotely, reducing diagnostic time and operational expenditure (OPEX). To fully leverage this, it is important to have a solid grasp of understanding key performance metrics, which is essential for optimizing the system's output over its lifetime.

System Reliability and Future-Proofing

A simpler electrical design with fewer points of failure can lead to greater system reliability. As noted in IEA analyses like Next Generation Wind and Solar Power, installing battery storage systems with distributed solar PV can increase self-consumption and improve grid interaction. The streamlined architecture achieved with RSD contributes to a more robust and efficient foundation for these advanced functionalities.

A New Perspective on Project Economics

This 1 MW PV-ESS case study demonstrates a critical shift in thinking. Safety compliance measures like Rapid Shutdown should not be viewed as an added cost but as an enabling technology. By strategically integrating RSD at the module level, the project achieved a substantial PV-ESS BOS cost optimization, reducing CAPEX by nearly 33% for key electrical components. This approach proves that thoughtful system design and component selection are paramount to improving the financial viability and long-term performance of large-scale solar and storage installations.

Frequently Asked Questions

What is Balance of System (BOS) in a PV-ESS project?

Balance of System (BOS) includes all the components of a photovoltaic and energy storage system other than the PV panels and the battery cells themselves. This encompasses inverters, wiring, mounting hardware, switchgear, monitoring systems, and the labor required for installation.

How does Rapid Shutdown (RSD) work?

Rapid Shutdown is a safety requirement for solar PV systems that provides a method to quickly de-energize the DC conductors from the PV array. This is typically achieved using electronics located at each module, which can be signaled to shut down, reducing the voltage in the array wiring to a safe level for firefighters or maintenance personnel.

What are the main drivers of BOS CAPEX in a 1 MW solar project?

In a megawatt-scale project, the primary drivers of BOS capital expenditure (CAPEX) are the cost of inverters, extensive DC and AC copper cabling, mounting structures (especially for ground-mount systems), switchgear, transformers, and the significant amount of skilled labor required for construction and commissioning.

Can RSD be retrofitted into existing systems?

Yes, it is possible to retrofit RSD capabilities onto older PV systems that were installed before such regulations were in effect. This typically involves adding module-level devices to the existing panels and integrating a new initiator switch. It is a common upgrade for enhancing the safety of existing installations.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.