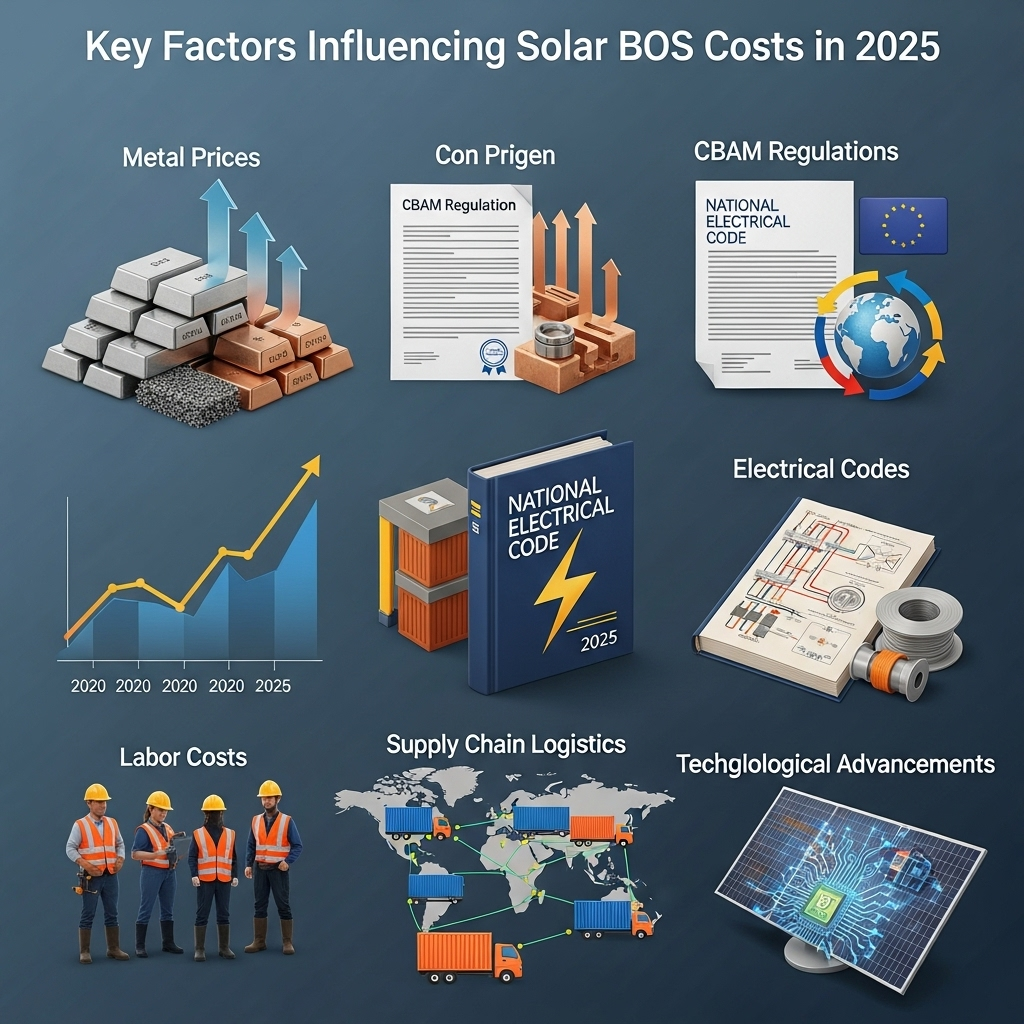

The financial viability of any solar energy project hinges significantly on its Balance of System (BOS) costs. These costs encompass all components outside of the photovoltaic modules themselves—from inverters and racking to wiring and labor. As the industry moves into 2025, a combination of factors, including volatile metal prices, new carbon regulations, and evolving electrical codes, is creating a complex cost landscape. Understanding these dynamics is critical for accurate project forecasting and maintaining competitive standing.

The Influence of Metal Markets on BOS Costs

The prices of raw materials are a foundational element in the BOS cost breakdown. Key industrial metals form the physical backbone of solar installations, and their market fluctuations have a direct and immediate effect on project budgets.

Key Metals in Solar Infrastructure

Steel and aluminum are the most prominent metals in a solar project's structure. Steel is prized for its strength and is heavily used in ground-mounted racking systems. Aluminum, being lightweight and corrosion-resistant, is a common choice for module frames and certain mounting applications. Copper is another critical component, essential for all electrical wiring that transmits power from the panels to the grid. The International Energy Agency (IEA) notes that rising commodity prices have reversed over a decade of cost reductions in solar PV. Price increases in these base metals directly translate to higher costs for racking, mounting hardware, and electrical components.

2025 Price Projections and Supply Chain Dynamics

Forecasting metal prices for 2025 involves navigating a web of global economic trends, mining outputs, and geopolitical factors. According to a report from the IEA, demand for materials critical for clean energy is growing rapidly. While supply chain disruptions have caused price spikes, efforts to increase the use of scrap metal in steel and aluminum production could introduce a stabilizing factor. However, overall demand, driven by the global energy transition, is expected to keep prices firm. Developers must account for this potential volatility in their BOS cost outlook for 2025.

Navigating the Carbon Border Adjustment Mechanism (CBAM)

A significant regulatory shift impacting the solar supply chain is the European Union's Carbon Border Adjustment Mechanism (CBAM). This policy is set to introduce new cost considerations for components imported into the EU.

What is CBAM and How Does It Affect Solar Components?

CBAM is essentially a tariff on the carbon emissions embedded in certain goods imported into the EU. Its goal is to prevent 'carbon leakage,' where companies move production to countries with less stringent emissions regulations. The mechanism specifically targets carbon-intensive materials like steel and aluminum, which are fundamental to BOS components such as mounting structures. While PV modules are not yet directly covered, the raw materials used in their support structures are. The transitional phase began in October 2023, with financial obligations expected to take full effect from 2026. Developers and importers can find the official legislative text and reporting requirements on the European Commission's CBAM page.

Anticipated Cost Impacts for 2025

For 2025, solar project developers importing steel and aluminum components from outside the EU will need to prepare for increased costs. The CBAM will require importers to purchase certificates corresponding to the carbon price of their goods, leveling the playing field with EU-based producers who operate under the Emissions Trading System (ETS). This will likely drive a shift in procurement strategies. Companies may begin to favor suppliers in regions with their own carbon pricing schemes or those who can demonstrate a lower carbon footprint in their manufacturing processes. According to the IEA's Projected Costs of Generating Electricity 2020, carbon pricing is a tool to make the true costs of different generation options more visible.

Case Study: Modeling CBAM Cost on a 1 MW Project

To illustrate the potential financial impact, consider a hypothetical 1 MW ground-mounted solar project in the EU using imported steel racking.

-

Project Assumptions:

- Steel required for racking: 40 metric tons.

- Origin of steel: A country with no carbon pricing.

- Embedded emissions of imported steel: 1.8 tCO2 per ton of steel.

- Assumed EU ETS carbon price in 2026 (when payment begins): €85 per tCO2.

-

Cost Calculation Formula:

Total CBAM Cost = (Tons of Imported Material × Embedded Emissions per Ton) × EU ETS Carbon Price -

Estimated Impact:

(40 tons steel × 1.8 tCO2/ton) × €85/tCO2 = €6,120

This represents a direct, added cost to the project's racking budget that must be factored into 2025 procurement planning for projects whose timelines extend into 2026.

Adapting to Evolving Electrical and Building Codes

Technical standards and safety regulations are constantly being refined. These code shifts, while beneficial for system safety and performance, often introduce new requirements that add to the BOS cost breakdown.

The Drive for Enhanced Safety and Performance

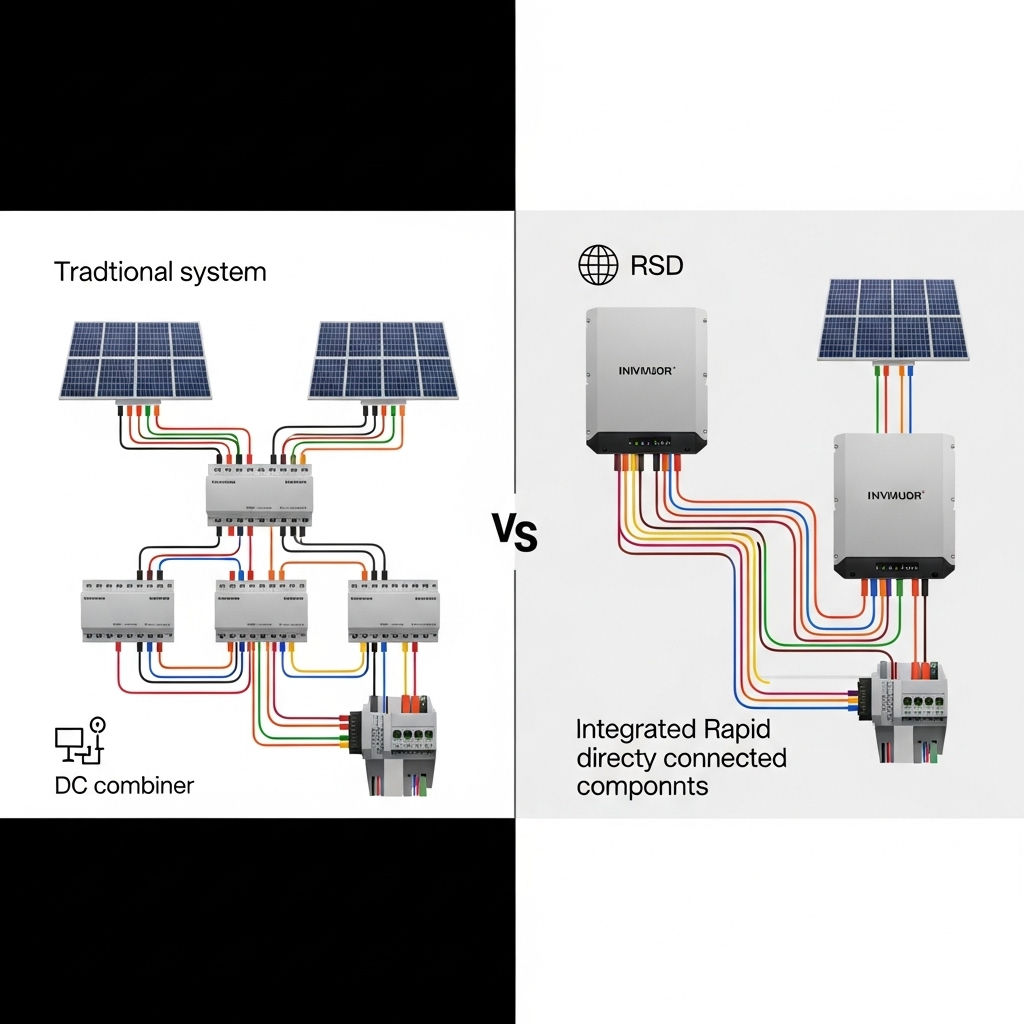

Updates to electrical codes, such as the National Electrical Code (NEC) in the United States, are designed to improve the safety and reliability of solar installations. The NEC 2023 revision, for example, introduced more stringent requirements for features like rapid shutdown, arc-fault protection, and ground fault protection. These mandates necessitate more advanced and, consequently, more expensive inverters, combiners, and other electrical hardware. While these changes enhance safety for first responders and maintenance personnel, they represent a tangible increase in upfront equipment costs.

Code Shifts on the Horizon for 2025

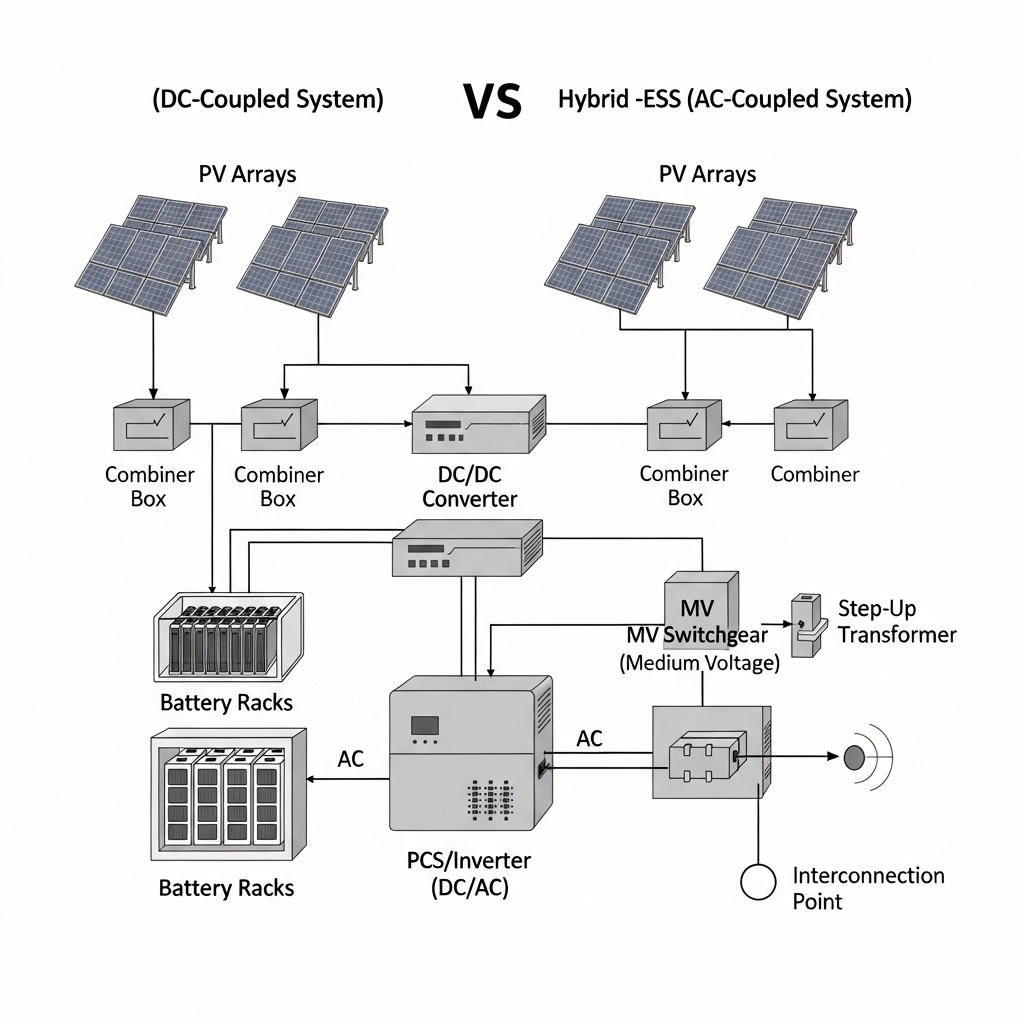

Looking ahead, code changes are likely to focus on the seamless integration of energy storage systems, enhanced cybersecurity measures for smart inverters, and standards for higher-voltage DC systems. Systems operating at 1500V or even 2000V are becoming more common in utility-scale projects to improve efficiency and reduce labor costs. However, these designs require specialized components and installation practices that can influence the overall BOS cost. For a detailed analysis of how different components contribute to system output, the ultimate reference for solar storage performance offers valuable insights into optimizing component selection for maximum efficiency.

Strategies for BOS Cost Optimization

Despite upward cost pressures, strategic planning and technological innovation offer pathways to mitigate rising BOS expenses. A proactive approach to procurement and system design can yield significant savings.

Procurement and Supply Chain Management

To counter the effects of metal price volatility and regulations like CBAM, diversifying the supply chain is crucial. Engaging with multiple suppliers across different geographic regions can reduce dependency on a single market and provide a buffer against localized price spikes or tariffs. Entering into long-term contracts with suppliers can also help lock in prices for essential materials like steel and aluminum, bringing more predictability to project budgets.

System Design and Technology Selection

Innovation in system design can directly lower BOS costs, particularly labor. Using pre-assembled and modular racking systems can drastically cut down on-site installation time. Furthermore, the adoption of integrated solutions, such as all-in-one energy storage systems that combine the battery, inverter, and management software into a single unit, simplifies installation and reduces the need for multiple discrete components. Choosing higher-efficiency components, though sometimes more expensive upfront, can lead to a lower Levelized Cost of Electricity (LCOE) over the project's lifetime.

Actionable Checklist for BOS Cost Management

- Supplier Vetting & CBAM: Request carbon footprint documentation from steel and aluminum suppliers. Prioritize those with lower embedded emissions or who are located in regions with carbon pricing schemes equivalent to the EU ETS.

- Contract Negotiation: Explore long-term framework agreements or volume-based discounts for critical components like racking and inverters to hedge against price volatility.

- Design-to-Cost Analysis: Model the trade-offs between higher-cost, labor-saving components (e.g., pre-assembled racking) and lower-cost, labor-intensive alternatives. Factor in local labor rates.

- Code Compliance Check: Confirm that all specified electrical components (inverters, combiners, disconnects) meet the latest adopted local code revisions (e.g., NEC 2023) to avoid costly redesigns or equipment swaps.

- Technology Tiering: For large portfolios, create a tiered procurement strategy. Use premium, high-efficiency components for space-constrained or high-irradiance projects, and more cost-effective options where land is abundant.

| Material | Initial Cost | Weight | Durability/Lifespan | Carbon Footprint (Pre-CBAM) |

|---|---|---|---|---|

| Galvanized Steel | Lower | Heavier | Excellent (25+ years) | Higher |

| Aluminum | Higher | Lighter | Excellent (25+ years, corrosion-resistant) | Lower |

Looking Ahead: The Future of BOS Costs

The Balance of System cost outlook for 2025 is a mix of challenges and opportunities. Volatile metal prices, pioneering carbon regulations like CBAM, and advancing safety codes will exert upward pressure on costs. However, the solar industry has a proven track record of resilience and innovation. Through strategic procurement, intelligent system design, and the adoption of integrated technologies, developers can effectively manage these variables. The continued focus on optimizing every aspect of a solar project beyond the modules will be paramount to achieving greater cost-efficiency and furthering the deployment of clean energy.

Frequently Asked Questions

What is the largest component of Balance of System (BOS) costs?

While it varies by project type, structural and electrical components, including racking, inverters, and wiring, typically make up a substantial portion of BOS costs. Labor for installation is also a major contributor. For utility-scale projects, civil work like site preparation and foundations can be a significant expense.

How will the CBAM directly impact a solar project's budget?

CBAM will directly increase the cost of importing carbon-intensive materials like steel and aluminum into the EU. This means that components like mounting structures and frames sourced from regions without a comparable carbon price will become more expensive, directly impacting the project's hardware budget.

Are there ways to reduce BOS costs without sacrificing quality?

Absolutely. Optimizing system design by using pre-fabricated components can reduce labor costs. Investing in higher-efficiency inverters can reduce the number of units needed and improve energy yield. Additionally, establishing long-term relationships with suppliers can provide more favorable pricing on components. The key is to look at the total lifetime cost, not just the upfront price.

Disclaimer: This article provides a general outlook on solar Balance of System (BOS) costs and is intended for informational purposes only. It is not a substitute for professional financial, legal, or engineering advice. Cost projections are subject to significant regional, regulatory, and project-specific variations. Readers should consult with qualified local experts before making any investment or procurement decisions.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.