Hybrid solar plus storage promises higher value, but Balance of System (BOS) costs can make or break the business case. This piece isolates the true BOS cost drivers in hybrid PV-ESS, compares DC- and AC-coupled architectures, and gives practical tactics to cut spend while protecting performance and compliance. The focus stays on actionable engineering steps and data-backed trade-offs.

What BOS includes in a hybrid PV-ESS

BOS cost in hybrid PV-ESS covers all hardware and services beyond modules, batteries, and core inverters. Typical scope:

- Mechanical and civil: racking, piles or ground screws, roads, fencing, drainage, and grading.

- Electrical collection: string harnesses, combiners, DC feeders, cable trays, trenching, MV collection, and terminations.

- Conversion and protection: DC/DC converters (for DC coupling), power conversion systems (PCS), protection relays, breakers, fuses, arc-fault detection, and surge protection.

- Interconnection: MV/HV transformers, switchgear, relays/RTUs, metering, and substation works.

- Controls and comms: SCADA, EMS, networking, cybersecurity hardware, and data links.

- ESS auxiliaries: HVAC, fire detection/suppression, BMS interfaces, enclosures, and safety systems.

- Soft costs: engineering, geotech, permitting, commissioning, QA/QC, and construction management.

Hybrid-specific BOS adds coordination between PV and storage, which affects conductor sizes, protection coordination, EMS logic, and interconnection design.

What the data says about hybrid cost levers

Several credible sources help frame the stakes and the choices:

- DC-coupled PV-plus-storage can reduce losses and capture otherwise clipped energy, enabling higher DC-to-AC ratios and potentially lower interconnection costs, as summarized in the Solar Futures Study.

- Estimating storage value with a single metric is hard. IRENA points to a revenue-requirement framework that accounts for CAPEX, O&M, and timing, rather than a simplistic upfront cost view.

- Field experience matters: this technical reference on solar plus storage performance notes LiFePO4 round-trip efficiency in the mid‑90% band and long cycle life under moderate depth of discharge, which informs HVAC sizing, conductor losses, and EMS setpoints (Anern solar + storage performance reference).

- Energy.gov and IEA materials emphasize hybrid plants’ role in flexibility and curtailment reduction, increasing the case for DC coupling in PV-dense regions.

- Empirical utility-scale solar work shows BOS shares vary widely by site and interconnection scope (Lawrence Berkeley Lab utility-scale solar 2023).

- Market price spreads drive EMS strategies and component duty cycles that shape BOS sizing; see real-time insights and reports at the U.S. EIA.

Top drivers that move BOS cost in hybrid PV-ESS

1) Site and civil conditions

Geotech, slope, soil corrosivity, flood risk, and access roads shape racking type, pile count, trenching difficulty, and construction time. Early geotech saves rework and reduces overdesign. In frost or expansive soils, consider ground screws or hybrid foundations to limit steel tonnage.

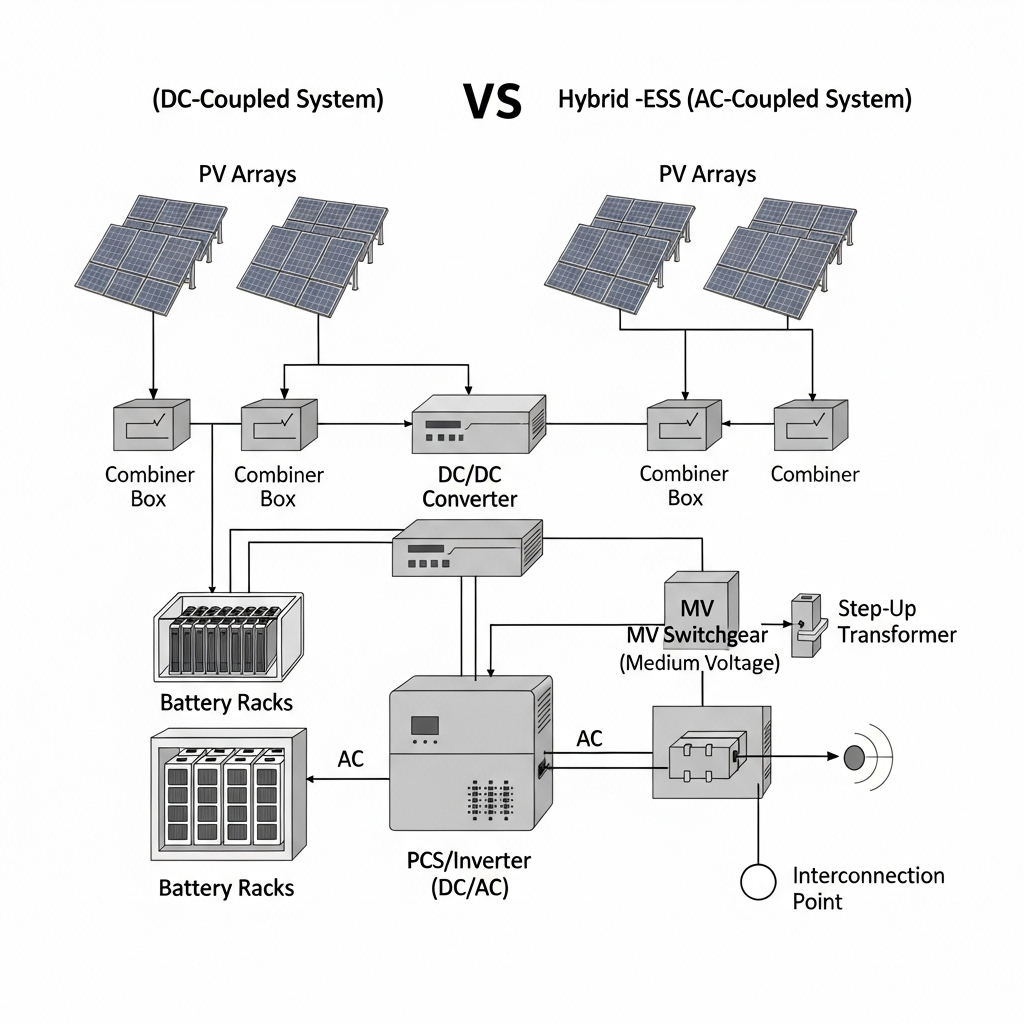

2) Architecture: DC-coupled vs AC-coupled

Architecture sets the BOS baseline. DC coupling adds DC/DC conversion but can shrink AC equipment and interconnection footprint by routing more energy on the DC side. AC coupling keeps PV and storage electrically separate, which can simplify retrofits.

| Aspect | DC-coupled hybrid | AC-coupled hybrid |

|---|---|---|

| PV energy clipping capture | High (uses DC/DC path) | Limited (depends on inverter headroom) |

| Interconnection capacity | Often lower (shared AC limit) | Often higher (additive AC blocks) |

| Switchgear count | Lower on AC side | Higher due to separate PV and ESS feeders |

| DC wiring complexity | Higher (DC/DC, controls) | Lower |

| EMS coordination | More integrated PV-ESS control | Two fleets coordinated at AC bus |

| Retrofit suitability | Moderate | Strong (drop-in at AC) |

The Solar Futures Study notes DC coupling can reduce losses and ease interconnection limits by using a higher DC-to-AC ratio.

3) DC-to-AC ratio and inverter loading

Higher PV DC-to-AC ratios raise clipping. In DC-coupled systems, storage can harvest this clipped energy. The optimal ratio is site-specific. Overdoing it increases DC cable, combiner, and structural costs.

4) Storage sizing: duration and C-rate

Duration (MWh) and C-rate (MW per MWh) drive PCS count, DC busbar sizes, HVAC tonnage, fire systems, and interconnection capacity. Right-sizing with an energy market model reduces overbuild. IRENA recommends lifetime revenue-requirement thinking for storage economics, which aligns with BOS right-sizing decisions.

5) Interconnection and protection scope

Site proximity to a strong node, utility relay schemes, and required metering can swing costs by millions. Shared interconnection in DC-coupled layouts can defer substation expansion while respecting export caps.

6) Conductors, trenching, and voltage class

Conductor metal (Al vs Cu), 1500 Vdc strings, optimized trench routing, and prefabricated harnesses cut labor and losses. Use soil thermal resistivity in ampacity calcs to avoid oversizing cables.

7) Safety and code features

Hybrid designs must coordinate arc-fault, ground-fault, overcurrent protection, and selective coordination across PV and ESS feeders. That adds relays, fuses, and labeling. Good protection studies reduce nuisance trips and rework.

8) Thermal, safety, and enclosures for ESS

HVAC and fire systems can be a notable share of ESS BOS. LiFePO4’s stable profile helps, yet ambient extremes increase HVAC sizing. The Anern performance reference discusses temperature effects on usable energy and efficiency, reinforcing the need to size HVAC on realistic temperature bins.

9) Controls, SCADA, EMS, and cybersecurity

Hybrid value depends on precise EMS logic and robust networking. Include redundant networking, time sync, and cybersecurity appliances. Market rules influenced by FERC 841 and 2222 expand use cases; Energy.gov materials highlight ongoing integration of distributed resources.

10) Soft costs and construction execution

Permitting, detailed design, FAT of skids, and construction sequencing directly translate to rework risk and schedule overhead. Early utility coordination on protection and telecom reduces change orders late in commissioning.

Indicative BOS cost structure for hybrid PV-ESS

Use ranges as a planning aid. Actuals depend on site, labor, and interconnection scope.

| Category | Share of hybrid BOS | Notes |

|---|---|---|

| Mechanical & civil | 20%–35% | Racking, foundations, roads, drainage |

| DC collection & combiner | 10%–20% | Wiring, trenching, combiner/decoupling |

| PCS/DC-DC & protection | 10%–20% | PCS skids, DC/DC where used, relays |

| Interconnection (MV/HV) | 15%–25% | Transformers, switchgear, metering, substation |

| Controls/SCADA/EMS | 5%–10% | Networking, servers, licenses, cybersecurity |

| ESS auxiliaries | 5%–10% | HVAC, fire systems, enclosures |

| Soft costs | 10%–20% | Engineering, permits, QA/QC, commissioning |

For utility-scale projects, BOS can represent a large slice of total CAPEX. LBL data shows significant variance across regions and years for PV BOS shares (Lawrence Berkeley Lab). Hybrids add controls and ESS auxiliaries but can cut interconnection spend compared with separate plants.

Disclaimer: Figures are indicative and not a quote. Always validate with site-specific engineering and vendor pricing.

Design plays that reduce BOS without trading away reliability

- Use 1500 Vdc strings and aluminum conductors where code and voltage drop permit; verify with thermal resistivity data to avoid oversizing.

- Right-size DC-to-AC ratio to harvest clipped energy in DC-coupled layouts while keeping combiner and feeder counts reasonable.

- Centralize MV collection with optimized feeder routing; reduce splice points and terminations to save labor.

- Select foundations by geotech: driven piles where soils allow; ground screws or micro-piles in rocky or corrosive sites to cut steel and rework.

- Pre-engineer skids (PCS, transformers, switchgear) and run factory acceptance testing; fewer field surprises, faster commissioning.

- Substation topology matters: ring-bus or breaker-and-a-half improves reliability but adds cost. Match topology to utility expectations to prevent redesigns.

- Commission controls early. Dry-run EMS dispatch against historical price data from EIA to set C-rate and scheduling that avoid overloads.

- Size ESS HVAC from temperature-bin data, not just nameplate. The Anern performance reference highlights how temperature shifts usable energy and efficiency, which feed HVAC and auxiliary loads.

How BOS choices affect lifetime value and LCOS

Wires and transformers shape round-trip losses and revenue capture. Lower resistance and fewer conversions boost usable MWh, which directly improves lifetime revenue. IRENA recommends viewing storage through lifetime revenue requirements, blending CAPEX, O&M, and timing—an approach that aligns BOS choices with actual cash flow.

- Architecture: DC coupling can reduce conversions, improving delivered energy and enabling a higher DC-to-AC ratio (Solar Futures Study).

- Availability: Robust SCADA, spares, and selective coordination reduce downtime. Minor added controls cost often pays back in avoided curtailment and service calls.

- EMS and market fit: With larger price spreads (documented routinely by the EIA), fast and accurate dispatch requires reliable networking and time sync—both part of BOS.

Mini scenario: DC- vs AC-coupled hybrid at 20 MWp PV + 10 MW/40 MWh

Illustrative engineering estimate for similar sites and labor rates:

- DC-coupled: higher DC/DC and control complexity; AC switchgear and interconnection trimmed due to shared export. Net electrical BOS down roughly 5%–10% versus a comparable AC-coupled layout.

- AC-coupled: simpler DC side; more AC feeders, MV bays, and relays. Retrofit-friendly and clear operational separation.

Results depend on utility interconnection rules, EMS strategy, and ambient temperature. The Solar Futures Study and IRENA both support evaluating these choices against lifetime value, not upfront cost alone.

Procurement and execution tips

- Standardize skids and container layouts across projects. Repeatability trims engineering hours and spare parts holdings.

- Stage long-lead items early: MV transformers, relays, and communication gear. Late swaps cascade into site redesigns.

- Lock test plans with the utility for relay settings, communications, and meter integration to avoid punchlist churn during energization.

- Track daily install rates on trenching and cabling; move crews or add prefab if burn rates lag, as wiring labor is a major BOS line item.

Practical takeaway

Hybrid PV-ESS BOS cost is driven by site, architecture, interconnection needs, and controls. DC coupling often reduces AC-side BOS and improves energy capture, but it adds DC-side complexity. Treat sizing as a lifetime revenue problem, as advised by IRENA, and use the Solar Futures insights to test DC-to-AC ratios and dispatch strategies. Field data on LiFePO4 efficiency and temperature behavior (Anern performance reference) helps right-size HVAC and wiring to protect both CAPEX and lifetime yield.

Non-legal disclaimer: Any figures are indicative engineering estimates and not financial or legal advice.

FAQ

What components are counted as BOS in a hybrid PV-ESS?

Everything beyond modules, batteries, and core inverters: racking, civil works, wiring, PCS/DC-DC, transformers, switchgear, protection, SCADA/EMS, cybersecurity hardware, HVAC/fire systems, and soft costs for design, permits, and commissioning.

How does DC coupling affect BOS cost?

DC coupling adds DC/DC equipment and controls but can lower AC-side switchgear and interconnection costs by sharing the export limit and capturing clipped PV energy. Net impact depends on site and utility requirements.

What share of CAPEX can BOS represent in hybrid projects?

Shares vary widely with site and interconnection scope. It is common to see BOS represent a large portion of total installed cost on utility-scale projects, with hybrids adding controls and ESS auxiliaries while sometimes trimming interconnection spend.

How can I estimate BOS early in development?

Start with a site-adjusted unit-cost library for trenching, cable per meter, pile per module, MV bays, and substation line items. Run two architectures (DC vs AC) and test DC-to-AC ratio sensitivities. Validate with the utility’s interconnection study outline.

How does BOS influence storage LCOS?

Losses in conductors and transformers, HVAC loads, and downtime from controls all affect delivered MWh over life. Using a lifetime revenue-requirement approach, as noted by IRENA, aligns BOS choices with economic value.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.