The price of solar panels has decreased dramatically, making solar energy more accessible. Yet, the panels themselves are only one part of the equation. The Balance of System (BOS) costs—everything else needed for a complete, operational solar installation—can account for a substantial portion of the total project expense. Understanding the BOS cost breakdown is critical for accurate budgeting and maximizing your return on investment. These costs are heavily influenced by regional standards, primarily the National Electrical Code (NEC) in the United States and International Electrotechnical Commission (IEC) standards used globally.

Core Components of Balance of System (BOS) Costs

Balance of System includes all the hardware and services required to get a solar PV system up and running, excluding the solar modules. These components ensure the system is mounted securely, electrically sound, and compliant with all regulations. A clear grasp of these elements is the first step in any BOS cost analysis.

Structural and Mounting Components

This category covers the physical framework that holds your solar panels. It includes racking, mounts, clamps, and rails. The cost here is influenced by the type of installation (rooftop, ground-mount), the materials used (aluminum vs. steel), and local environmental factors. For instance, areas with high wind or heavy snow loads require more robust—and often more expensive—mounting solutions to ensure long-term stability.

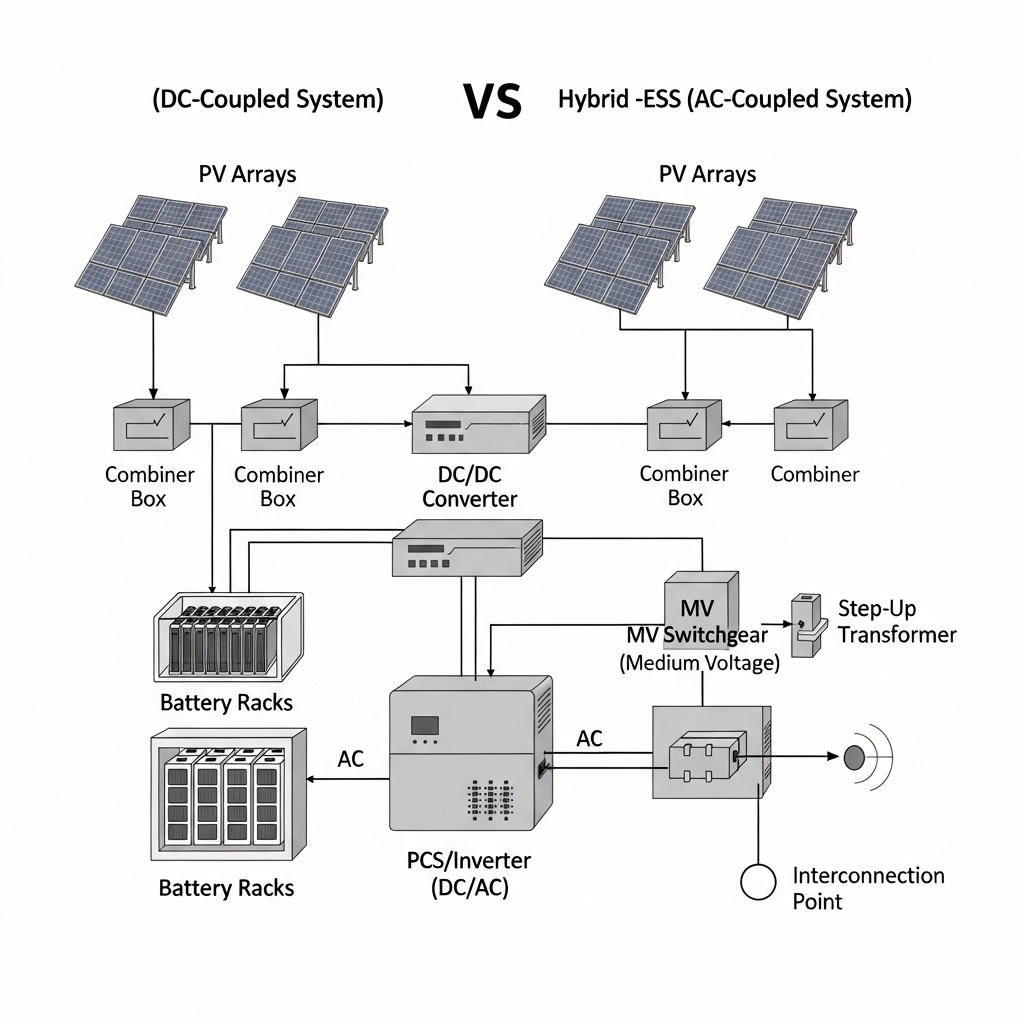

Electrical Components

The electrical infrastructure is the heart of the BOS. This includes the inverter, which converts DC electricity from the panels to AC electricity for your property. It also covers all wiring, conduit, combiner boxes, fuses, circuit breakers, and disconnect switches. Safety devices, such as rapid shutdown systems mandated by the NEC, are also a significant part of this cost category. The choice between string inverters, microinverters, or power optimizers will create substantial variations in the electrical BOS budget.

Soft Costs

Often underestimated, soft costs are non-hardware expenses. These include system design and engineering, labor for installation, permitting fees required by local authorities, and the cost of interconnection with the utility grid. The complexity of the local code and permitting process can directly impact these figures. A streamlined process reduces labor hours and administrative overhead, while a complex one adds to the final price.

How NEC and IEC Standards Shape BOS Expenditures

The NEC and IEC have different philosophies that result in distinct hardware and design requirements. The NEC, updated every three years, is generally more prescriptive, with detailed rules aimed at ensuring safety, particularly for first responders. IEC standards are often more performance-based, allowing for a wider range of solutions to achieve safety and operational goals. This divergence is a primary driver in the BOS cost factors under NEC/IEC.

Wiring and Conduit Requirements

Wiring practices show a clear difference between the two standards. The NEC often specifies strict requirements for conduit types (e.g., metal conduit in certain locations) and wire management to protect against physical damage and environmental exposure. This can increase material and labor costs. In many IEC jurisdictions, installers may have more flexibility, such as using appropriately rated, UV-resistant DC cabling without conduit in certain applications, which can lower expenses.

Safety Mandates: The Rapid Shutdown Example

Perhaps the most significant cost differentiator is the NEC's requirement for rapid shutdown (RSD). NEC 690.12 mandates a way to de-energize conductors on a roof quickly, protecting firefighters from electrical hazards. Compliance typically requires module-level power electronics (MLPE) or specialized inverters, adding a component and labor cost that is absent in most regions following IEC standards. While some IEC countries have specific disconnect rules, they are not typically as extensive as the NEC's RSD mandate.

Grounding and Overcurrent Protection

Grounding philosophies also differ. The NEC has very specific rules for grounding electrode conductors and equipment grounding. These rules dictate the size and type of materials used. Overcurrent protection device (OCPD) sizing and placement are also meticulously defined. While IEC standards ensure safety, their guidelines can allow for different, sometimes less materially intensive, approaches to achieve the same level of protection, impacting the final BOS cost breakdown.

Strategic Optimization of BOS Costs Under Both Standards

Regardless of the governing code, strategic decisions in design and procurement can significantly reduce BOS expenses. Optimization is not about cutting corners but making intelligent choices that deliver safety and performance efficiently.

Component Selection and System Design

Choosing highly integrated components is an effective strategy. For example, some modern inverters come with built-in DC disconnects and RSD functionality, reducing the need for separate external boxes and the associated labor. A thoughtful system layout that minimizes the length of wire runs directly cuts down on copper costs, which can be substantial. As the International Energy Agency (IEA) notes in its Advancing Clean Technology Manufacturing report, efficiencies in technology and manufacturing are key drivers of cost reduction across the clean energy sector.

Labor and Installation Efficiency

Labor is a major soft cost. Using pre-assembled components, rail-less mounting systems, or plug-and-play wiring solutions can accelerate installation time. Crucially, investing in training for installers on the specific nuances of the local code—be it the latest NEC edition or a national implementation of an IEC standard—prevents costly errors and rework that lead to budget overruns.

Evaluating System Performance vs. Upfront Cost

The lowest upfront BOS cost does not always equal the best value. It is vital to consider the Levelized Cost of Energy (LCOE), which accounts for the system's lifetime energy production against its total cost. Investing more in a highly efficient inverter or durable racking might increase the initial BOS price but pay for itself many times over through higher energy yield and lower maintenance expenses. For a deeper analysis of how different components affect long-term output, consulting a guide on solar and storage performance metrics provides valuable insights into making these trade-offs.

A Comparative Look at a 10 kW System: NEC vs. IEC

To illustrate the differences, this table offers a simplified comparison of BOS cost drivers for a typical residential system. The actual costs can vary widely, but the relative differences highlight the impact of code requirements.

| Component/Factor | Typical NEC Jurisdiction (e.g., USA) | Typical IEC Jurisdiction (e.g., Germany) | Key Cost Driver |

|---|---|---|---|

| Rapid Shutdown System | Required ($$$) | Not typically required ($) | NEC 690.12 Mandate |

| DC/AC Disconnects | Specific external disconnects often required ($$) | Often integrated into inverter ($) | Code Prescription |

| Conduit/Wiring | Stricter requirements (e.g., metal conduit) ($$$) | More flexible options (e.g., direct burial cable) ($$) | Material & Labor |

| Labor & Permitting | Higher due to complexity ($$$) | Streamlined in some areas ($$) | Regulatory Overhead |

| Estimated BOS Cost Impact | Higher | Lower | Cumulative Effect |

Disclaimer: This table provides a general comparison for illustrative purposes. Actual costs depend heavily on the specific location, equipment manufacturers, and installer.

Final Thoughts on Strategic BOS Management

The Balance of System is a complex but manageable part of any solar project budget. The costs are not static; they are a direct result of design choices, component selection, and the regulatory framework you operate within. A deep understanding of whether your project falls under NEC or IEC guidelines is the foundation of effective BOS cost optimization. By focusing on smart design, integrated components, and installation efficiency, you can build a safe, compliant, and financially successful solar energy system that moves you closer to energy independence.

Frequently Asked Questions

What percentage of a total solar project cost is BOS?

BOS costs can represent a significant portion, often ranging from 30% to 50% of the total cost of a solar PV system. This percentage can fluctuate based on system size, location, and the specific components chosen.

Does NEC compliance always mean higher BOS costs than IEC?

Generally, the prescriptive safety requirements of the NEC, such as rapid shutdown, can lead to higher upfront hardware and labor costs compared to many IEC-compliant systems. However, costs are project-specific, and efficient design can mitigate some of these differences.

How can I optimize my BOS cost factors under NEC/IEC?

Focus on integrated components to reduce parts and labor, optimize your layout to minimize wire lengths, and select mounting systems suited for your specific site. Always work with installers who are experts in the local codes to avoid expensive revisions.

Is the inverter part of the BOS cost?

Yes, the inverter is a major electrical component and a key part of the Balance of System cost breakdown. Its selection significantly impacts both the price and performance of the entire system.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.