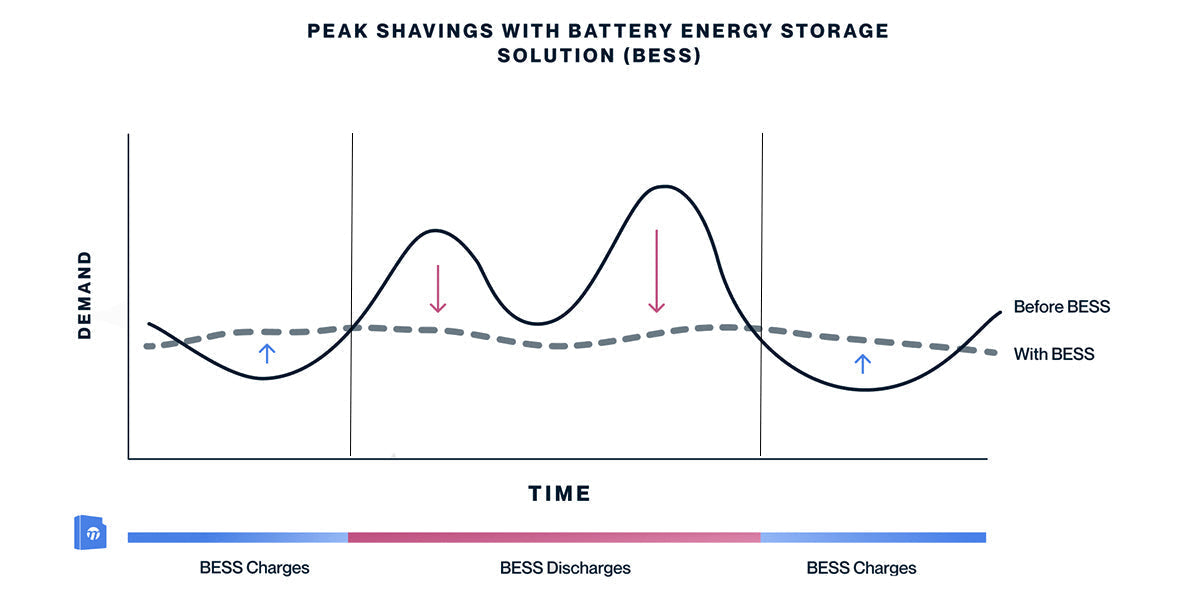

Demand charges can turn a stable budget into a guessing game. A practical playbook changes that. This guide focuses on actions that help teams apply lithium-ion batteries to cap peaks, hold billed demand within a target range, and prove results with clean measurement. You will see how to read the tariff, size a system with a small reserve, operate with simple rules, and scale the approach across sites.

Which Bill Items Can Commercial Battery Storage Actually Cut?

Every dollar of savings starts with the tariff. Identify the interval the utility uses to set billed demand, then study when peaks occur and how long they last. A commercial battery storage system addresses those short windows and trims the highest kilowatts without disrupting operations.

Start with three checks:

Confirm the 15- or 30-minute demand interval and any seasonal on-peak windows.

Export 12–24 months of interval data, list the top peaks with start time and duration, and tag recurring patterns.

Look for a ratchet clause or power-factor penalties that influence the achievable reduction.

How to Size Lithium-Ion Batteries for Business Peak Shaving

Sizing works best when the team follows the same routine at every site. The aim is a lithium-ion battery configuration that hits the target cap comfortably and keeps reserve for back-to-back events.

Step 1: Gather Load and Tariff Data

Collect interval data, billing summaries, process schedules, and any planned electrification that may raise future peaks. Note the toughest season and the likely on-peak window.

Step 2: Choose the Cap Target

Select a kilowatt reduction that aligns with operations. Sharp, brief peaks invite a higher cap reduction than long afternoon plateaus. Keep the target realistic for the first quarter of operation.

Step 3: Estimate Required Energy

Translate the cap into energy. Multiply the target kilowatts by the typical peak duration in hours. Apply a reserve factor near 1.15 to cover efficiency and control margins. Maintain a state-of-charge floor in the high teens so the system can respond again if a second peak forms.

Step 4: Verify Power and Lifetime

Confirm that inverter power matches the cap level and that the cycle count fits the warranty plan. Check round-trip efficiency and thermal limits for the local climate. Lithium-ion batteries respond quickly and tolerate frequent partial cycles, which supports accurate capping.

How to Use Battery Storage for Peak Shaving Day to Day

Daily operation turns a design into line-item savings. A light-touch control scheme often delivers the most reliable results.

Plan the Charge Window

Enter the on-peak period with a healthy state of charge. Pick low-load hours for charging so production stays undisturbed.

Set the Discharge Trigger

Dispatch when the forecaster load approaches the cap threshold. Hold a steady power level rather than chasing every small fluctuation.

Protect State of Charge

Keep a firm SoC floor to cover a second peak later in the day. Recover the state of charge as soon as the major event ends.

Deal with Outliers

Some spikes do not repay the energy required to contain them. Define a stop rule for those cases to avoid draining reserves.

Tune Weekly

Review the week’s top events, adjust the cap a little if needed, and shift the charge start time by small increments. Sites using battery storage for peak shaving often find that these tiny adjustments create steady gains in billed demand reduction.

What’s the ROI for a Commercial Energy Storage System Under Demand Charges?

Finance teams want a short model they can trust each month. Build one page that adds avoided demand charges and any approved program revenue, then subtracts annualized costs for equipment, software, service, and insurance. Track payback, IRR, and NPV with a few sensitivity cases such as ratchet presence, peak frequency, and tariff updates. Interval-based measurement keeps the discussion grounded. Compare billed demand before and after, link reductions to specific peak events, and keep assumptions visible. With consistent control, lithium-ion batteries hold power output across the event window, which helps the numbers stay predictable. The phrase ROI for commercial energy storage systems deserves more than a spreadsheet; it needs month-over-month transparency.

Site Checks and Risks: What Can Limit a Lithium-Ion Battery Strategy?

A short survey avoids surprises during permits and commissioning. Review interconnection capacity, transformer loading, power-factor rules, harmonic limits, fire code spacing, ventilation, and thermal design. Confirm BAS or SCADA integration with low latency, define protection and islanding behavior, and plan a bypass path for maintenance. Align insurance language and service response times before an order. Each item protects uptime and keeps savings on schedule for the lithium-ion battery system.

Implementation Playbook: Pilot to Scale Using Lithium-Ion for Business

A repeatable path takes the guesswork out of expansion. Run a focused pilot, lock the template, then deploy to similar sites with confidence. This is how lithium-ion for business becomes standard practice rather than a one-off project.

Pilot

Pick one meter with frequent peaks. Set a clear cap target and weekly review rhythm. Publish a short monthly note that shows billed demand before and after, plus any control changes.

Template

Freeze the data fields you always collect, the control parameters you always set, and the alarm routing you always follow. Document the measurement method so finance and operations speak the same language.

Rollout

Build a tariff catalog for all regions, duplicate the template, and track the same KPIs in a single dashboard. Schedule quarterly tune-ups to reflect process changes or new loads.

Scaling ROI using Battery Storage for Peak Shaving

Real savings come from steady habits. Teams read the tariff carefully, model the peak shape, and size the system with a modest reserve. Operations run a simple rule set that charges ahead of the on-peak window and discharges as the cap approaches, then verify results with interval data and a short KPI set. When a pilot shows consistent reduction in billed demand, the template carries that success to the next site. In practice, lithium-ion batteries give managers a controllable way to calm monthly swings and build confidence in the numbers.

FAQs

Q1. We don’t have interval data. How can we start sizing and savings estimation quickly?

Request a utility export like Green Button or AMI CSV first. If that’s delayed, deploy temporary loggers on the main feeder for two to four weeks, aligned to the utility’s 15 or 30-minute window. Pull SCADA or BMS trends as a cross-check. Build the pilot using the worst observed peaks.

Q2. How should the system behave during outages or when a generator is present?

Set the EMS to suspend peak-shaving discharge on grid loss unless the site is configured for islanding. Coordinate with the ATS so the generator inrush does not trip the limits. Reserve capacity for ride-through, test transfer sequences quarterly, and define a clear black-start and safe-shutdown procedure.

Q3. What incentives or financing structures can improve ROI right now?

Standalone storage may qualify for a federal investment tax credit and accelerated depreciation in the U.S., subject to prevailing program rules. Utilities may also pay for demand response participation. Consider energy-as-a-service or shared-savings agreements to reduce upfront capital while keeping performance transparent through contracted M&V.

Q4. What IT and cybersecurity baseline should we require for the EMS?

Place the EMS on a segmented VLAN with outbound-only connections, TLS encryption, and VPN for remote access. Use role-based accounts, MFA, and audit logs. Keep an offline fallback schedule for controls. Apply change control for firmware, and whitelist IPs for vendor support to limit exposure.

Q5. What O&M plan keeps savings consistent over time?

Review KPIs monthly and investigate the variance in the same week. Update firmware and run alarm drills each quarter. Perform thermal scans of cabinets, clean filters, and verify fan operation. Calibrate meters annually and run a controlled capacity test. Stock critical spares and enforce a response-time SLA.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.