Clear labels and clean as-builts cut questions at the job site. Inspectors see facts at a glance. You reduce rework. This playbook focuses on PV/ESS labeling requirements and documentation tactics that help you pass AHJ inspections with fewer surprises.

What AHJs expect to see on PV/ESS jobs

- Permanent, easy-to-read PV and ESS labels with consistent color, size, and wording.

- As-builts that match the field build: conductor sizes, OCPD ratings, equipment schedules, and grounding.

- Evidence that interconnection and two-way power flows are safe and documented.

- Rapid access to datasheets, test records, and signage plans.

Fast approvals begin with standards-based thinking. Clear testing, benchmarking, and performance classes are the backbone of reliable labels and documentation. This aligns with the labeling scheme elements described by the IEA: Transforming Global Markets for Clean Energy Products—testing protocols, benchmarking, and performance requirements form a defensible approach.

PV/ESS labeling that passes in the field

Color, materials, and legibility

Use durable materials and high contrast. Many AHJs accept red backgrounds with white, all‑caps text for PV DC hazards, and yellow or red for energy storage hazard warnings. UV-stable polyester or engraved phenolic plates resist fading. Use adhesive that bonds to powder coat and textured enclosures. For character height, a commonly accepted minimum for hazard labels near service equipment is 3/8 in (≈9.5 mm). Confirm local requirements, as some AHJs ask for larger text on outdoor equipment.

| Label topic | Typical field-proven spec | Purpose | Notes |

|---|---|---|---|

| PV DC circuit hazard | Red background, white text, 3/8 in letters, UV-stable | Immediate shock/arc warning | Permanent, weather-resistant; place on raceways and near combiner/DC disconnect |

| Rapid shutdown | Reflective, exterior-rated, symbol + wording | First responder clarity | Position at service equipment and main disconnect |

| AC point of interconnection | Yellow/black or red/white, 3/8 in letters | Backfeed awareness | Clearly mark service equipment line/load and supply-side taps |

| ESS hazard & chemistry | Yellow/black, chemistry stated (e.g., LiFePO4) | Fire and emergency response | Include nominal kWh, voltage, and shutdown method |

| Directory placard | White/black, engraved plate | System map for responders | Show all disconnects and their locations |

For context on standardization benefits, the IEA Solar PV Technology Roadmap notes how robust standards reduce early failures, while also highlighting gaps that AHJs bridge with clear local labeling expectations. Where local guidance is thin, anchor your approach in durability, readability, and permanence.

Placement that reduces questions

- At service equipment: interconnection label, rapid shutdown label, and directory placard grouped together.

- On conduits: identify PV DC polarity and function at entry/exit points and every pull point.

- On ESS: chemistry, nominal energy (kWh), nominal voltage, shutdown procedure, and working clearances.

- At roofs or remote arrays: labels at access points indicating PV circuits present.

QR linking to documentation

Attach a weatherproof QR code sticker near the main directory placard. Link to a read-only packet: as-builts, datasheets, torque logs, and commissioning notes. Field teams report smoother conversations when inspectors can scan at the meter and view project specifics on the spot. A performance reference adds context: the Ultimate Reference: Solar Storage Performance compiles typical lithium storage data, including round‑trip efficiency ranges near 90–95% for LiFePO4 and cycle life in the low‑thousands at 80% DoD. Those numbers help explain energy throughput and battery labeling values. Actual values vary by product and temperature; reflect your installed equipment.

As-builts that answer inspector questions

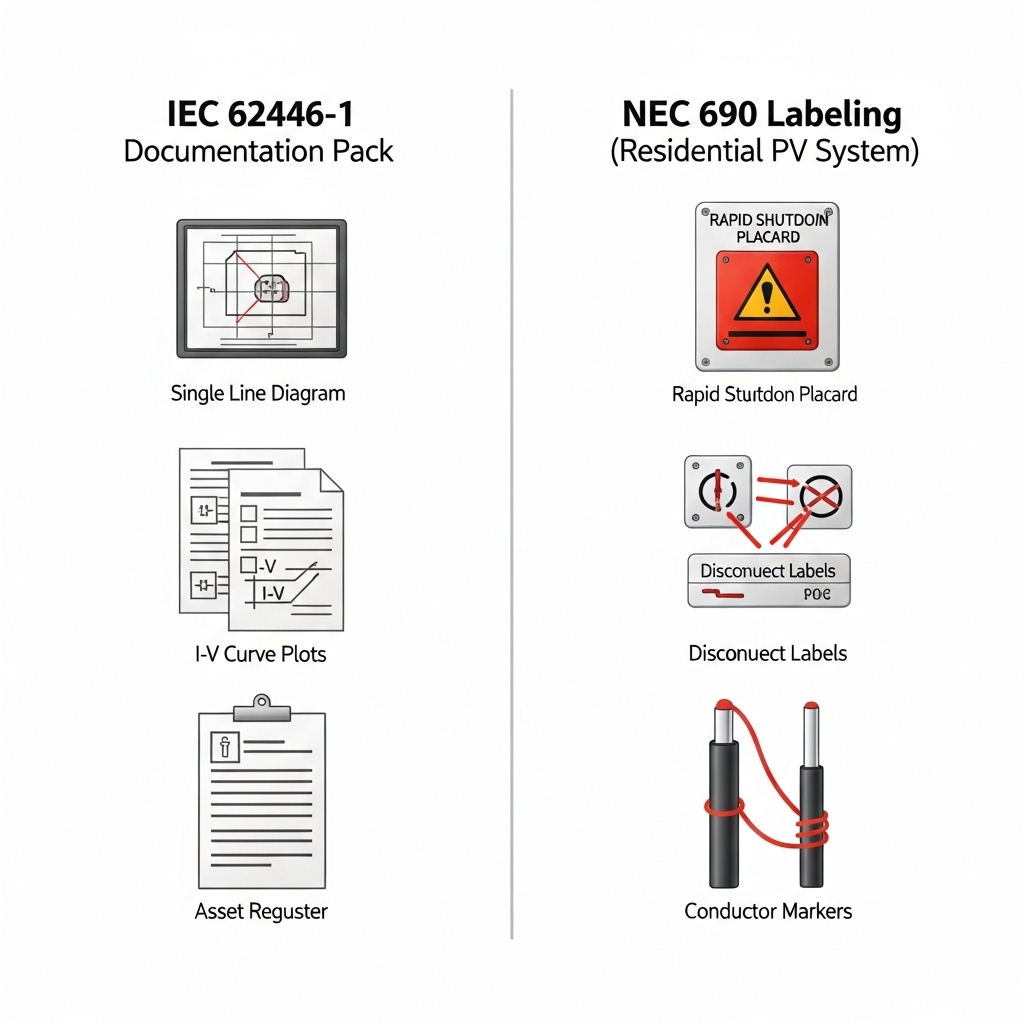

What the single-line diagram should show

- Array configuration: module count, strings, max voltage at the site’s design minimum temperature.

- Conductors, raceways, and OCPD: size, type, insulation rating, ampacity basis, and derates.

- Inverter/charger functions: modes, transfer rating, anti-islanding, and output overcurrent protection.

- ESS details: chemistry, nominal Wh/kWh, BMS shutdown path, short-circuit current rating, and disconnects.

- Grounding and bonding: GEC, EGC, electrodes, and connections.

- Point of interconnection: load or supply side, bus rating, breaker size, or tap detail.

Site plan and equipment schedule

Provide a scaled plan showing clearances around the ESS, ventilation paths if applicable, working space at disconnects, and signage locations. List equipment with ratings, environmental class, and mounting method. Consistency matters: the as-built set must match the field labels. A mismatch between label text and the SLD legend is a common cause of red tags.

| As-built component | What to include | Why it helps |

|---|---|---|

| Single-line diagram | Voltages, currents, OCPD, grounding, ESS ratings, operating modes | Addresses electrical safety and functional operation |

| Site plan | Equipment locations, working clearances, signage placements | Confirms access and emergency response layout |

| Conductor/raceway table | Types, sizes, ampacity base, derate math | Shows code-calculated capacity and thermal limits |

| Equipment schedule | Ratings, SCCR/interrupting rating, environmental specs | Verifies suitability and short-circuit coordination |

| Label legend | Exact wording, colors, materials, locations | Aligns field labels with drawings and avoids reprints |

| Commissioning notes | Functional checks, torque logs, firmware list | Documents readiness and traceability |

AHJs are also focused on safe two-way flows. The IEA manual on integrating wind and solar highlights planning for bi-directional power and managing constraints. A precise interconnection diagram and backfeed labeling directly support that goal.

Pre-inspection checklist that fits a 30–45 minute window

- Match labels to the legend: verify wording, color, character height, and placement on every device and raceway.

- Torque sampling: confirm a subset of terminals against manufacturer specs; record values in the packet.

- Shutoff paths: test rapid shutdown indication and ESS shutdown procedure; document normal and emergency steps.

- QR packet scan test: open on a phone at weak signal; provide a printed backup in the panel directory.

- Panel schedules and bus ratings: verify interconnection math and breaker handle ties or hold-downs as installed.

- Housekeeping: clear working spaces, label conduits at penetrations, cap unused knockouts, tidy wire labels.

Evidence and references that strengthen your submission

- Growth pressure is real. EIA reporting shows rapid expansion of distributed PV, so AHJs face more volume. Clean packets reduce review time.

- Energy.gov on Solar provides safety basics and responder considerations you can echo in signage and directory placards.

- The IEA labeling framework supports the idea of standardized testing, benchmarking, and performance classes—useful logic for label content and as-built consistency.

- The IEA PV Roadmap discusses qualification standards for modules; include module certificates and environmental ratings in your packet to reduce questions.

- IEA grid integration guidance stresses planning for two-way flows—address this with clear POI labels and interconnection math.

- IRENA aggregates best practices on renewable deployment; citing recognized bodies signals a mature compliance approach.

- Use performance ranges from the Solar Storage Performance reference to contextualize ESS behavior on labels and in as-builts (efficiency and cycle life vary with temperature and DoD).

Regional and building-code context

Labeling and thermal safety principles often benefit from broader building-policy thinking. The IEA Morocco 2019 policy review shows how performance-based and prescriptive approaches can work together for buildings. That same two-tier mindset helps on PV/ESS jobs: performance data in the packet plus prescriptive labels on gear. Standardized methods and material specs make your work more defendable during an AHJ visit.

Common pitfalls and fast fixes

- Mismatched ratings: label says 200A bus, schedule shows 225A. Fix the schedule and reprint the label.

- Non-permanent labels: vinyl decals on rough powder coat peel early. Switch to engraved plates or premium UV laminates.

- Unreadable at distance: 3/16 in text on outdoor gear. Increase to 3/8 in or larger and re-place nearer eye level.

- Missing ESS chemistry: add ‘LiFePO4’ plus kWh and shutdown instructions to the ESS label set.

- QR dead link: host on a stable, versioned folder with public read-only access; include a short URL on the placard.

Case snapshot: tying labels to as-builts

A residential 9–12 kW PV with a mid-size LiFePO4 ESS passes on the first try when the team uses a label legend in the drawing set, stamps the same text on hardware, and anchors interconnection math next to the panel schedule. The inspector scans the QR, checks torque notes and shutdown steps, and signs off without requesting reprints. Small habits—like keeping label text in the SLD title block—avoid inconsistencies late in construction.

Why performance data belongs in the packet

Inspectors often ask how the ESS behaves under heat or at high load. Include a brief performance note drawn from the Solar Storage Performance reference to set realistic expectations for round‑trip efficiency and usable energy across temperatures. Tie that note to your label legend so the ESS kWh value on the enclosure aligns with your as-built assumptions.

Final notes

Make labels permanent, consistent, and easy to read. Keep as-builts current and aligned to the field. Link everything with a QR sticker that works offline via a printed backup. These habits reduce guesswork and speed AHJ inspections.

Compliance and safety information here is for general education only and does not constitute legal advice or engineering approval. Always follow your local AHJ, fire authority, and utility requirements. Non-legal advice.

FAQ

What label size and wording do inspectors expect?

Many accept 3/8 in (≈9.5 mm) characters for hazard labels on service equipment and larger text outdoors. Keep wording short, in all caps, with high contrast. Confirm local rules and keep spelling identical to your label legend.

Do QR codes replace physical labels?

No. Physical labels remain required. The QR supplements them with as-builts, datasheets, and commissioning notes so inspectors can verify details quickly.

What should be in an as-built set for PV+ESS?

Include the SLD, site plan, equipment schedule, conductor and raceway table, label legend, interconnection details, shutdown steps, and commissioning notes. Match all values to field conditions and equipment nameplates.

How do I address two-way power flow concerns?

Show the AC point of interconnection clearly, label backfeed points, and include interconnection math. This aligns with planning guidance outlined in the IEA grid integration manual.

Should I include performance data for the ESS?

Yes, briefly. Reference trusted sources like the Solar Storage Performance reference and align kWh, efficiency, and DoD assumptions with what is printed on the ESS label.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.