Labels and documents decide how fast a solar-plus-storage project gets energized. Inspectors, utilities, and fire marshals rely on them to verify safety, code conformity, and system intent. Incomplete placards or thin paper trails are a common reason for red tags and utility delays. With years in solar and storage, across residential and C&I sites, I’ve seen that a precise labeling plan saves days on commissioning and reduces callbacks.

Standards also improve trust and lower transaction cost. The U.S. Department of Energy highlighted how PVQAT and IEC 62941 raised confidence in manufacturing quality and traceability, supporting long‑term performance assurance and bankability (Energy.gov, EERE Success Story—International PV Manufacturing Standards Improve Investor Confidence). IRENA and IEA research shows that grid codes and technical standards shape equipment behavior and compliance expectations, which flow into field labeling and documentation requirements for PV and ESS (IRENA 2022; IEA 2019).

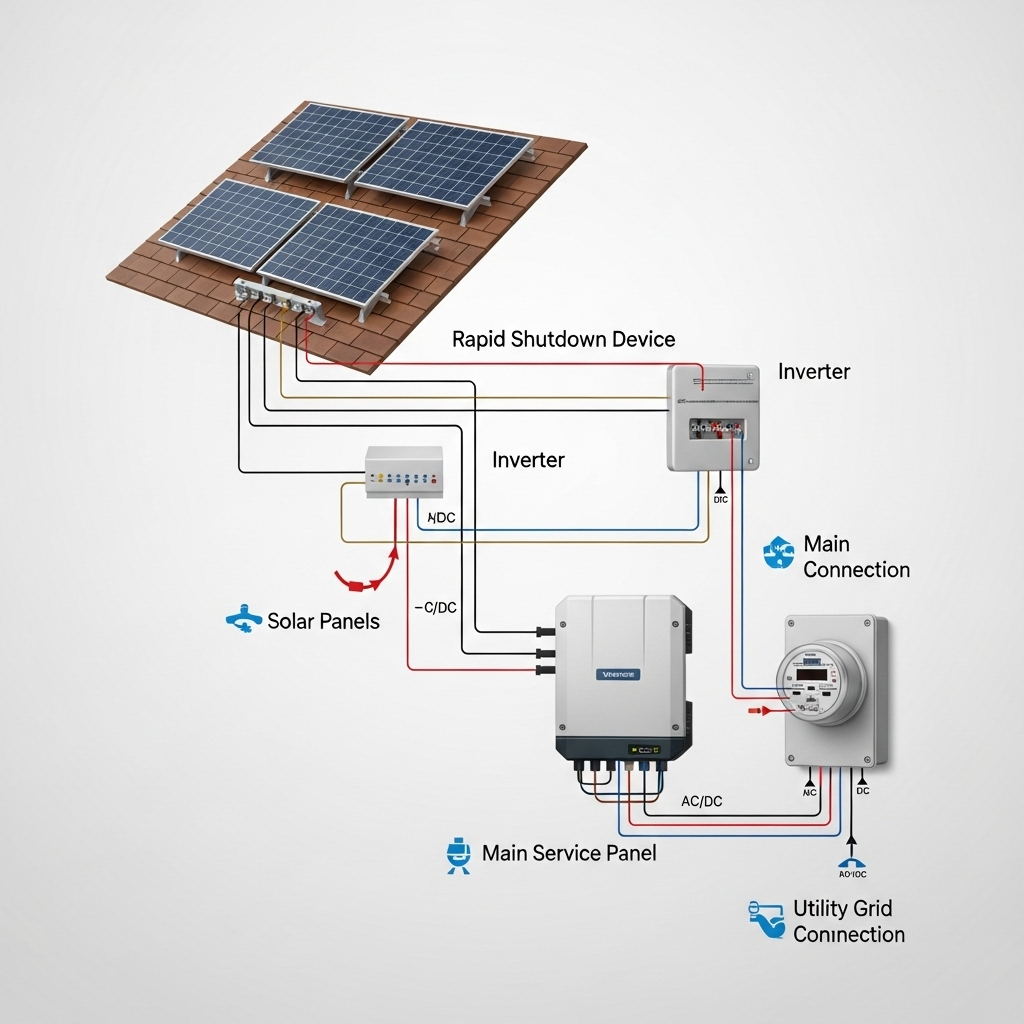

This resource maps labeling requirements, documentation requirements, BOS standards, NEC requirements, IEC standards, and RSD documentation into a practical workflow. It also shows where ANERN equipment and document packs fit, and it links to deeper reads such as Ultimate Guide to NEC/IEC Labeling and Documentation for PV+ESS and How to Pass AHJ Inspections: PV/ESS Labels and As-Builts.

1. Foundations: Codes, Standards, and BOS Scope

1.1 What labeling and documentation cover on PV+ESS sites

- PV array and BOS: source circuits, combiners, disconnects, inverters, raceways, junction boxes, and directories.

- ESS: battery cabinets or racks, power conversion system (PCS), BMS, disconnects, fire signage, and emergency shutdown labeling.

- RSD: placards and directories that inform responders and operators where rapid shutdown is initiated and which conductors are controlled.

- Project documentation: design one-line, site plan, equipment datasheets, calculations, commissioning and test records, O&M materials, and as-builts.

For a structured overview that you can hand to the team, see Ultimate Guide to NEC/IEC Labeling and Documentation for PV+ESS.

1.2 NEC vs IEC: scope and alignment

- NEC focus: installation safety in the U.S., with parts that heavily impact labels and placards: Articles 110, 690, 705, and 706.

- IEC focus: documentation and test evidence that systems meet design and safety objectives. IEC 62446‑1 sets a clear dossier for PV documentation and commissioning records.

- Grid codes and interconnection: IEEE 1547 and UL/CSA standards influence equipment markings and instructions; they also inform AHJ expectations for labels and manuals. NERC guidance emphasizes inverter-based resources and clarity in interconnection requirements, which often show up in the document set inspectors ask to see.

See the side-by-side summary in IEC 62446-1 vs NEC 690: What Each Demands in PV Documentation.

1.3 Standards improve reliability and paperwork quality

IRENA’s 2022 report on grid codes notes that international standards and grid codes reinforce each other. Consistent labeling and documentation reduce ambiguity during inspections and operations. DOE’s account of PVQAT and IEC 62941 shows how standardized quality management, traceability, and audits improve confidence and reduce redundant checks—benefits that extend to site labeling and documentation discipline (Energy.gov; IRENA; IEA).

2. NEC Requirements That Drive PV/ESS Labels and RSD Documentation

2.1 Core code hooks

- NEC 110.21(B): field-applied hazard markings need durable construction, suitable contrast, and legible text size.

- NEC 690 (PV): equipment labeling, circuit identification, and RSD placards per 690.12 and 690.56(C).

- NEC 705 (power production interconnections): directories and identification of all power sources feeding a service.

- NEC 706 (energy storage systems): identification and hazard markings, disconnect labels, and instructions near the ESS.

| Label or Placard | Typical Code Reference | Content Focus | Placement |

|---|---|---|---|

| PV DC source label | NEC 690.31, 690.53 | Max DC voltage/current, short‑circuit current, and wiring identification | At inverter DC input, combiner outputs, or DC disconnect |

| Inverter AC output label | NEC 690.54 | AC output voltage, current, and frequency | Near inverter AC output terminals or AC disconnect |

| Directory of power sources | NEC 705 | Locations of PV, ESS, and other sources feeding the service | At service equipment and at each distribution equipment as required |

| Rapid shutdown placard | NEC 690.56(C) | RSD status, initiation method/location, and conductor control boundary | At service equipment and at RSD initiation device |

| ESS identification/hazard label | NEC 706.10; NFPA 855 | Chemistry, voltage, capacity, emergency operations, and hazards | On ESS enclosure and near ESS disconnects |

For a practical checklist that aligns with both inspectors and utility reviewers, start with Installer Checklist: NEC PV Labels, Placards, and As-Builts.

2.2 RSD documentation and on-site placards

Rapid Shutdown (RSD) needs two things: a placard that informs responders and a documentation set that proves the design controls the intended conductors. Provide a one-line with an array boundary reference and show the initiation device clearly. Keep the RSD equipment datasheet, listing, and a verification test record in the closeout package. Label the initiation device and place the placard at service equipment per 690.56(C). For specifics, see Which Labels Are Mandatory Under NEC 690.56(C) for PV RSD? and the context in Myth vs Reality: Are NEC Rapid Shutdown Labels Overkill?.

2.3 ESS room signage and fire code

Energy storage spaces need signage that supports first responders. Identify chemistry (for example, LiFePO4), energy capacity, shutdown steps, and ventilation or clearance notes. NFPA 855 and the International Fire Code (IFC) add requirements for room signage, access, spacing, and in some cases hazard mitigation plans. See ESS Room Signage: NFPA 855 and IFC Requirements Explained.

3. IEC Standards and the Documentation Dossier

3.1 IEC 62446‑1 document set

IEC 62446‑1 defines the baseline dossier many AHJs appreciate even in NEC jurisdictions: design documentation, equipment datasheets, array strings and cable routing, labeling schedule, test records, and O&M documents. The commissioning bundle typically includes continuity checks, polarity checks, insulation resistance, I‑V measurements where applicable, functional tests, and RSD verification. See Commissioning Blueprint: IEC 62446-1 Test Records That Pass.

3.2 Labeling references under IEC

- IEC 60364‑7‑712 and IEC 62446‑1: prescribe labels for PV DC, AC, and isolation points; require clear indication of multiple power sources and emergency controls.

- Use internationally recognized safety symbols for electrical shock, DC, and emergency stop. Keep color and symbol usage consistent with IEC norms.

For a practical comparison with NEC-driven labeling plans, refer to IEC 62446-1 vs NEC 690: What Each Demands in PV Documentation.

3.3 Cross-border projects

Projects designed for shipment or installation across multiple regions benefit from a hybrid pack: NEC labels and placards on U.S.-bound units, IEC symbol-based labels plus local language where required, and a shared commissioning test record format. Align inverter and ESS nameplates with both sets where possible to avoid rework.

4. Documentation Requirements That Pass AHJ and Utility Reviews

4.1 As-built and closeout package

- Stamped as-built one-line and site plan, including conductor IDs that match label text.

- Labeling schedule: each label ID, material spec, text, color, and physical location.

- RSD package: placard text, initiation device location, RSD datasheets and listing, and verification test record.

- ESS package: BMS datasheet, battery chemistry, nameplate voltage/energy, disconnect scheme, emergency procedure, and signage details.

- Commissioning records per IEC 62446‑1 or local template: continuity, polarity, insulation resistance, functional tests.

- O&M manual, warranty terms, and owner training log.

Workflow tips and templates: How to Pass AHJ Inspections: PV/ESS Labels and As-Builts and 12 Must-Have Documents for NEC 690/706 Compliance in ESS.

4.2 Utility interconnection submittal

- Interconnection one-line with protective settings, anti-islanding listing, and labeling callouts for disconnects and directories.

- RSD placard reference and shutdown initiation location. Include a photo mock-up when possible.

- Voltage rise calculation and feeder loading notes if requested, matched to labels on equipment ratings.

Utility screeners often reject packages over missing placards on drawings or conflicting ratings between datasheets and label text. See 7 Labeling Mistakes That Trigger Utility Rejections. For common field misses, see Data-Backed: Common Labeling Failures Found in ESS Audits.

4.3 Aligning documents with field reality

Bring a label kit and the labeling schedule to site. Apply labels as the installer terminates, not at the very end. Photograph each label in place and embed those photos in the as-built set. This simple habit turns a tough AHJ visit into a short walkdown with clear evidence.

5. Designing Durable PV/ESS Labels That Survive

5.1 Materials, contrast, and legibility

Choose materials that meet environmental exposure. Field-applied hazard markings should follow NEC 110.21(B) for durability and legibility. For long service life, select materials and adhesives listed to UL 969 or equivalent. Where sunlight and weather are harsh, use outdoor-rated films and inks with UV resistance. Helpful deep dives: Roadmap to UL 969-Compliant PV Labels that Last 10+ Years and Stop Red Tags: Design Durable PV/ESS Labels that Survive.

| Attribute | Recommendation | Why it matters |

|---|---|---|

| Base material | UV-rated polyester or polycarbonate; engraved phenolic for hot surfaces | Resists fading and cracking outdoors |

| Adhesive | Acrylic, high-bond, outdoor grade | Stays attached on painted metal and textured plastic |

| Contrast | High contrast (e.g., black on yellow; white on red for emergency) | Improves readability and hazard recognition |

| Letter height | At least 9.5 mm for equipment labels; larger for placards | Meets common legibility expectations |

| Environmental rating | Outdoor UV, moisture, and abrasion resistance; temperature-rated | Prevents early fade and delamination |

5.2 Placement and verification

- Place labels where a technician naturally looks during operation or lockout/tagout.

- Keep wire markers consistent with drawings and include circuit polarity signs for PV DC.

- Install the RSD placard at service equipment and near the initiation device. Add a directory map if the property is large.

- Scan for glare and obstruction. A readable label in shade beats a perfectly centered label that blinds in sun.

5.3 Tools and templates

Prebuilt templates reduce typos and maintain code wording. Industrial label printers with UV-stable ribbons are worth the cost on multi‑day jobs. For product picks and template packs, see Tools Review: Label Printers and Templates for NEC PV Sites.

6. ANERN Solutions, Performance Data, and Compliance Support

6.1 How ANERN equipment supports compliant labeling

ANERN’s focus includes LiFePO4 lithium batteries, integrated ESS for homes, off‑grid solar solutions, and solar inverters. Projects benefit from clear product nameplates, downloadable datasheets, and labeling schedules aligned with NEC and IEC expectations. Typical inclusions:

- ESS enclosure nameplates: model, nominal voltage and energy, rated current, and serial number for traceability.

- Battery documentation: chemistry (LiFePO4), BMS functions, wiring, and safety notes that feed directly into ESS room signage.

- Inverter documentation: AC ratings and interconnection notes that match AC output labels and utility forms.

- Optional label kits: placards for RSD, directories of multiple sources, and circuit ID markers that match the design one-line.

This streamlines both labeling requirements and documentation requirements across BOS standards. It also reduces rework during AHJ visits.

6.2 Performance data that informs safe and clear labels

Label text should not fight physics. State nominal voltage and energy clearly. Include recommended charge/discharge ranges and environmental limits in O&M documents posted near the ESS. ANERN’s performance reference compiles practical figures for storage system sizing and operation. For example, LiFePO4 systems are known for high cycle life and stable round‑trip efficiency, with typical operating windows that support daily cycling. See ANERN’s data and practical notes in Ultimate Reference: Solar + Storage Performance. Those figures help set realistic labels for capacity, power ratings, and temperature ranges, and they support tester pass/fail thresholds during commissioning.

6.3 Project workflow with ANERN

- Design: select ANERN LiFePO4 batteries and hybrid inverters sized to the load profile; build a label schedule that mirrors equipment ratings.

- Procurement: download product datasheets and the label schedule; prepare RSD placard and directory plates in advance.

- Installation: apply labels as each device is set; verify color, text, and placement against the schedule.

- Commissioning: run tests per IEC 62446‑1 style records; capture RSD verification and embed photos of each critical label.

- Handover: deliver a digital and printed package that includes drawings, datasheets, test records, and O&M with emergency instructions.

How a disciplined label refresh cut delays is summarized in Case Study: Labeling Overhaul Slashes ESS Inspection Delays.

7. Stepwise Plan: From Design to Commissioning

7.1 Design phase

- Create a single source of truth: the one-line diagram with label callouts and tag numbers.

- Draft RSD placard text and show initiation location on the site plan.

- Prepare the ESS signage text: chemistry, nominal voltage and energy, shutdown steps, and contact numbers.

7.2 Installation phase

- Label critical points as soon as conductors are terminated.

- Confirm wire markers match the drawing tags for each source circuit and combiner output.

- Mount the directory and RSD placard at service equipment; add an exterior placard if required by local fire code.

7.3 Commissioning and handover

- Run polarity, continuity, insulation resistance, and functional tests; record values and photos.

- Verify RSD operation and document the measured results according to your acceptance criteria.

- Deliver the final package: as-builts, test records, equipment datasheets, warranties, and O&M.

Practical FAQs and Tips

Do I need both a directory and RSD placard?

In most NEC installations with multiple sources, yes—a directory identifies all sources at the service, and the RSD placard addresses firefighter needs and shutdown. See Installer Checklist: NEC PV Labels, Placards, and As-Builts.

Can I reuse old placard designs on new code cycles?

Only if they match the current code language and intent. Update wording, boundaries, or icons when code requirements change. The comparison in IEC 62446-1 vs NEC 690 helps clarify differences.

What gets projects flagged most often?

- Missing RSD placards at the service point.

- Faded or non‑durable labels that don’t meet 110.21(B) intent.

- Directories that omit the ESS or misstate the interconnection point.

For trends from field audits, check Data-Backed: Common Labeling Failures Found in ESS Audits.

Key Takeaways

- Map labels directly to NEC 690/705/706 and local fire code expectations; in non‑U.S. settings, build the IEC 62446‑1 dossier.

- Make labels durable and legible; plan placement for real‑world use and safety.

- Lock the process: one-line with callouts, early label application, photo verification, and a clean closeout package.

- Use ANERN equipment data and the performance reference to keep nameplate and O&M facts aligned with real capabilities: Ultimate Reference: Solar + Storage Performance.

Standards and grid codes continue to evolve. IRENA and IEA note that harmonized requirements reduce friction and improve integration of inverter‑based resources into modern grids. A strong labeling and documentation plan fits that direction and keeps projects on schedule.

Compliance note: Codes and standards cited here are summarized for convenience. Local amendments, utility rules, and fire code provisions vary by jurisdiction. Always confirm with the AHJ, utility, and fire authority. This content is for informational purposes and is not legal advice.

Further Reading

- Ultimate Guide to NEC/IEC Labeling and Documentation for PV+ESS

- How to Pass AHJ Inspections: PV/ESS Labels and As-Builts

- 12 Must-Have Documents for NEC 690/706 Compliance in ESS

- IEC 62446-1 vs NEC 690: What Each Demands in PV Documentation

- Stop Red Tags: Design Durable PV/ESS Labels that Survive

- Which Labels Are Mandatory Under NEC 690.56(C) for PV RSD?

- Tools Review: Label Printers and Templates for NEC PV Sites

- Data-Backed: Common Labeling Failures Found in ESS Audits

- Case Study: Labeling Overhaul Slashes ESS Inspection Delays

- Roadmap to UL 969-Compliant PV Labels that Last 10+ Years

- ESS Room Signage: NFPA 855 and IFC Requirements Explained

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.